Vacuum Lifters

Bradley Lifting designs and manufactures heavy duty vacuum lifting equipment for customers with specialized requirements. Vacuum Lifters are generally used for handling materials that are non-magnetic, thin and difficult to grasp with other lifting devices, susceptible to surface / edge marking or damage, and single sheet handling from a stack.

Our Vacuum Lifters emphasize safety by using “ready-to-lift” vacuum monitoring systems, on-board / integral reservoirs for loss of power conditions and heavy-duty vacuum pads. Ranging in size from single pad lifters to multi-zone, articulating pad lifters on telescoping and/or rotating beams, Bradley Lifting can design a vacuum lifter system to meet your specific requirements.

Single Pad Vacuum Lifters

For lifting materials of moderate size and with a relatively rigid structure, a single pad vacuum lifter may be the best solution. Bradley Lifting has designed numerous single pad lifters to accommodate loads with a variety of shapes (rectangular, circular or curved) and surface finishes. Other factors that must be considered are temperature, porosity of the material and availability of vacuum or power sources on the crane.

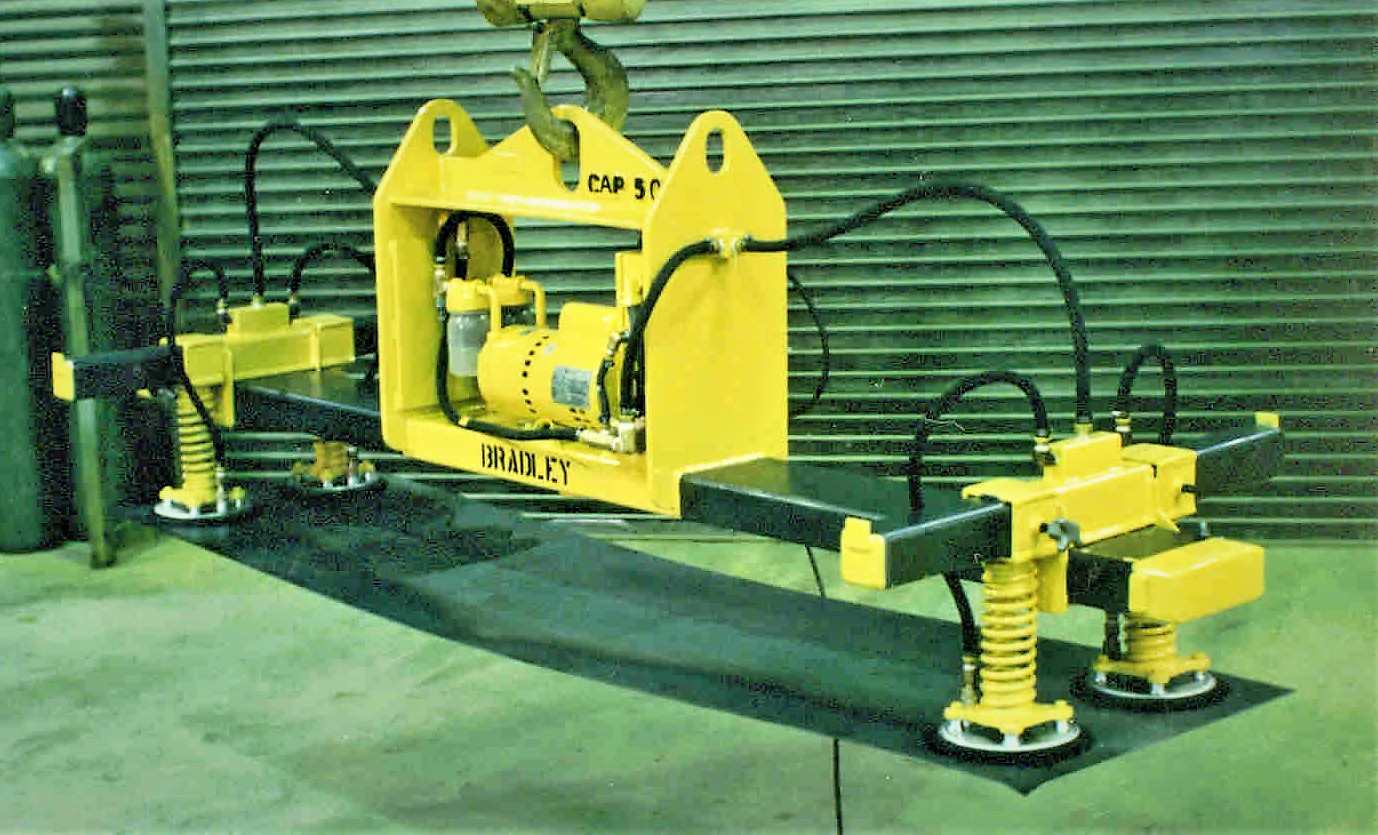

Multiple Pad Vacuum Lifters

For heavier loads or large surface areas, multiple pad vacuum lifter designs are available. Multiple Pad Vacuum Lifters are appropriate for lifting materials with large surface areas, significant deflections during a single point lift (e.g. thin sheets), major changes in area from load to load, or large variations in contour of the lifting surface.

To meet customer requirements, Bradley Lifting engineers will often incorporate the ability to telescope (manual or motorized) and to rotate within the Multiple Pad Vacuum Lifter. Other factors that must be considered are temperature, porosity of the material and availability of vacuum or power sources on the crane.

Asked & Answered

Q: How do I determine the number of vacuum pads that I need for my application?

A: The force generated by a vacuum lifter is a function of the surface area of the vacuum pads. A Bradley engineer can help determine the size, number, and orientation of vacuum pads that you will need to best fulfill your application.

Q: What is the maximum temperature sheet that a vacuum lifter can handle?

A: Bradley vacuum pads are designed to handle surface temperatures of up to 400°F.

Q: What connections must be run from my crane to the vacuum lifter?

A: There are three crane connection options that can be chosen when designing your Bradley vacuum lifter. The first, and most common, is to connect the vacuum lifter to your existing crane power supply. The second option is to connect the vacuum lifter to an existing source of compressed air. The third, and simplest, option is to connect the vacuum lifter to an existing vacuum pump mounted on your crane. If your crane does not have any of these capabilities, Bradley can provide a battery powered vacuum lifter, which does not require any connection between your crane and the vacuum lifter.

GET ANSWERS