Lifting Beams

Lifting Beams (sometimes referred to as Spreader Beams) are, at first glance, relatively simple devices. However, it takes a knowledgeable and experienced supplier to produce a lifting beam that is reliable, safe and maximizes the efficiency of a customer’s operation. Bradley Lifting manufactures Lifting Beams that are suitable for mill-duty service by incorporating keyed and welded connections, closed section members, reinforced joints and high strength alloy steel in wear or damage prone areas.

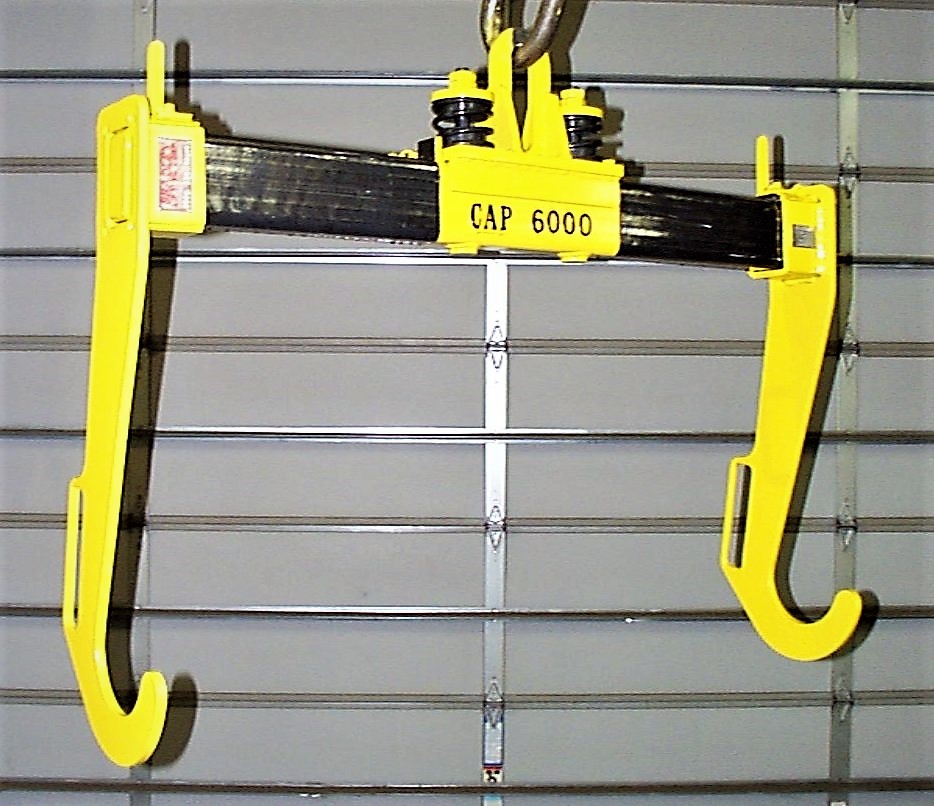

J-Hook Lifting Beams

J- Hook Lifting Beams are an excellent solution for handling of Rolls, Shafts, and other Round materials. The hook spacing, radius, and length can all be customized to suit your needs. Fixed hooks and manual or motorized adjustable hooks are also available.

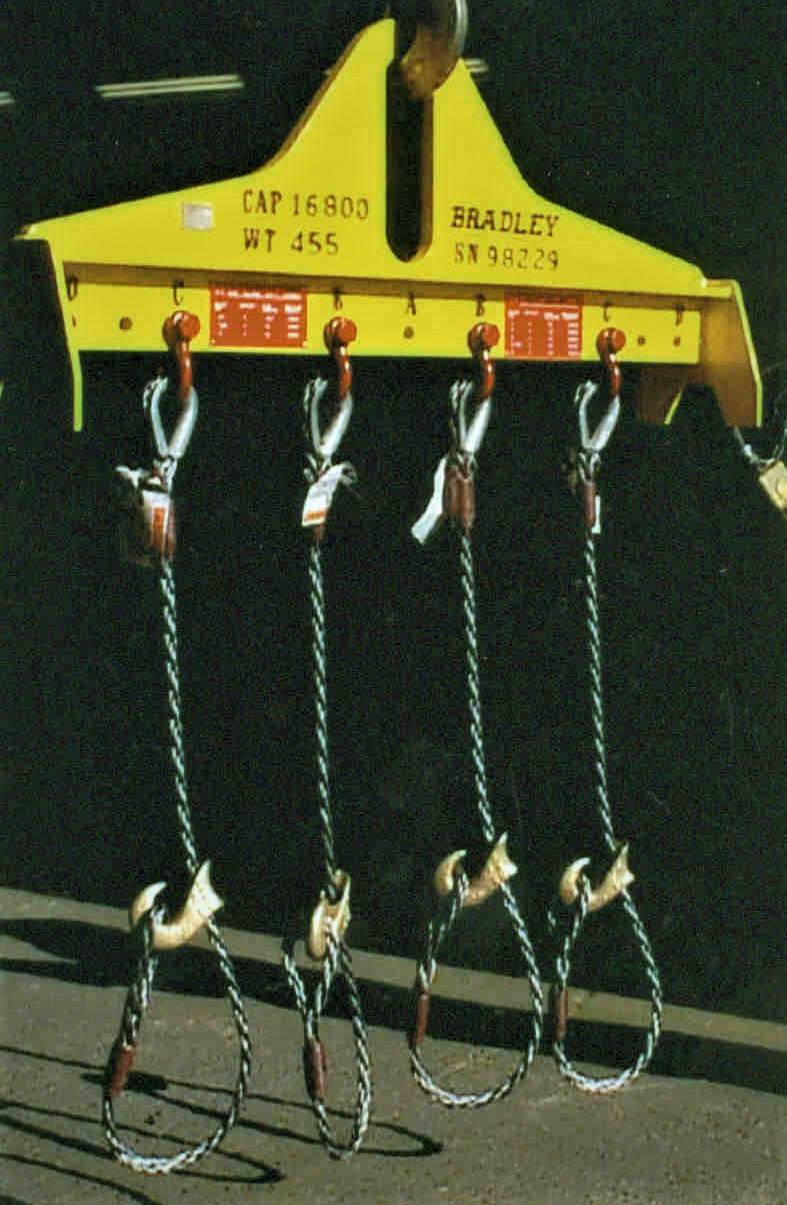

Sling Lifting Beams

Lifting beams (often called spreader beams also) are the backbone for connecting other lifting accessories such as slings, wire chokers, chains, etc.to form a complete lifting system. Fully customized configurations are available.

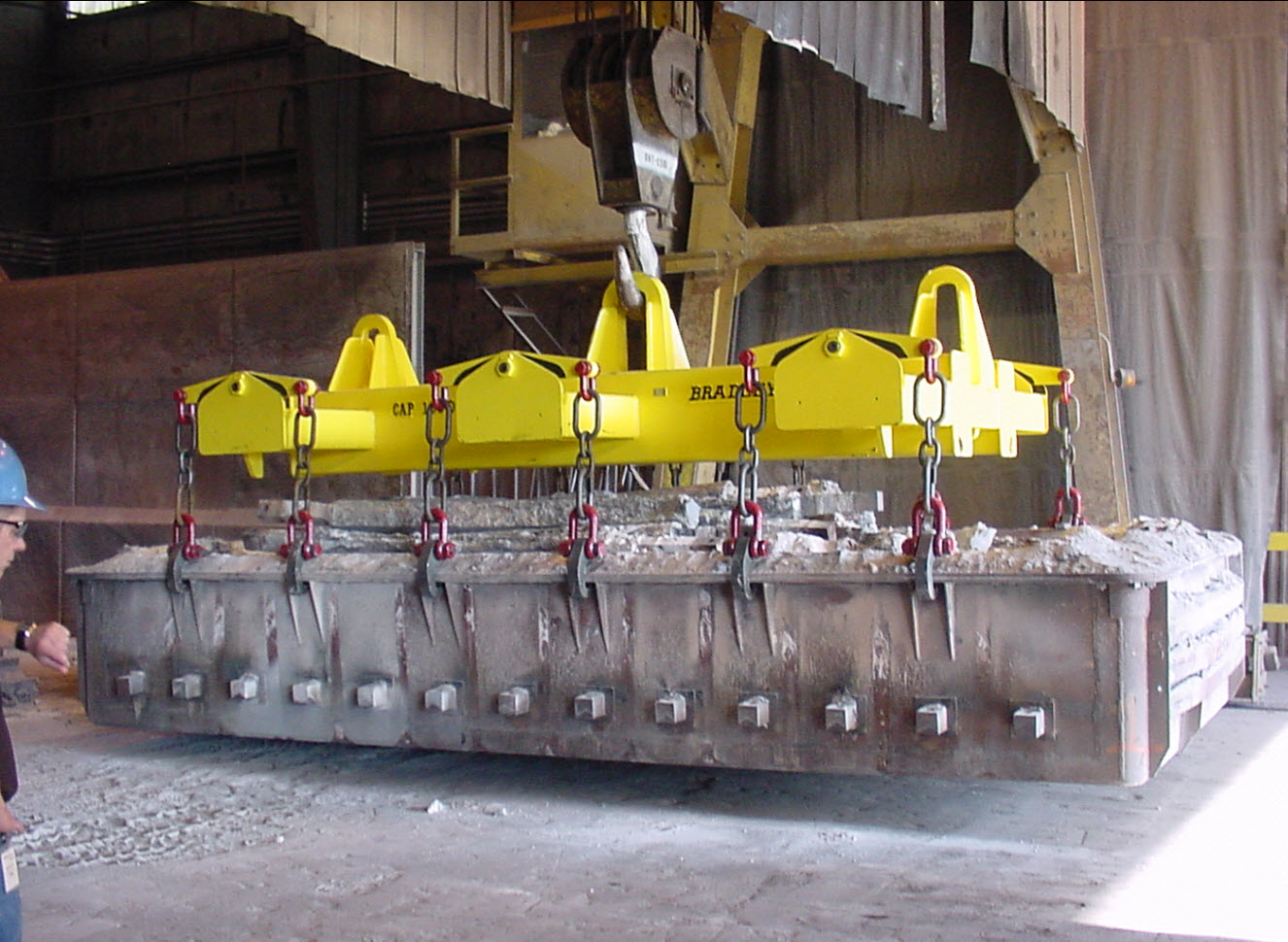

Custom Lifting Beams

For the most “unique” lifting applications, Bradley Engineers can design a completely custom lifting beam to suit your needs. Whether it is intended for heavy-duty production, or limited maintenance use, we will design the beam to your specific parameters. Unlimited configurations are possible, call us today to speak with a Bradley Applications Engineer to discuss your lifting solution.

Telescoping Lifting Beams

To meet customer requirements, Bradley Lifting engineers will often incorporate the ability to telescope (manual or motorized) and to rotate within the Multiple Pad Vacuum Lifter. Other factors that must be considered are temperature, porosity of the material and availability of vacuum or power sources on the crane.

Magnetic Lifting Beams

Lifting Beams can be custom-configured to accommodate your existing magnets for handling anything from single plates to rows of billets or bundles. Bradley offers fixed beam or manually adjustable and motorized adjustable designs to suit any lifting application. These rugged beams are designed to handle the heavy shock loads typical of magnet handling applications and can also be pre-wired to provide plug-and-play functionality.

Asked & Answered

Q: What information is needed to design a custom lifting beam for my application? A: We will need to know the capacity and dimensions of the loads you are handling. Center-of-gravity information may be required for asymmetrical loads. The available crane capacity, the dimensions of the rigging points, and any clearance or headroom limitations will also be necessary to properly design your lifter. As always, photos, sketches, and drawings will be extremely helpful.

Q: What methods are best for attaching the load to your lifting beam? A: We can provide a multitude of options for this. Traditional wire rope, chain, or nylon slings are most common, with end attachments specifically suited to the loads you wish to carry.

Q: What features are offered to help protect the surfaces of my products? A: We can offer protective linings to help minimize marking of the loads to be handled. UHMW polyurethane is just one example material that is often used.

GET ANSWERS